Blog Layout

Understanding the Nickel Chrome Plating Process

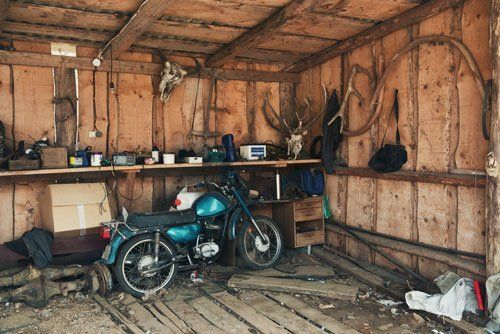

If you need chroming to protect or restore the wheels on your motorcycle, you will need to understand the process by which chroming is seen to completion. Not every vehicle is a good candidate for chroming, but if yours is, you will see many benefits from this decision. Given how difficult it is to chrome plate a metal part, you should leave the task to professionals.

How Chromium Works

Chrome is short for chromium. It is a metal that is applied as a thin layer over another surface rather than being used as a solid object. Some parts that are very shiny are referred to as chrome by a layperson, but for it to actually be chrome, it must use chromium. Parts made with chrome are more reflective and bluer. They are also more reflective.

Chrome can make your ride much more beautiful and improve its value. It is designed to be durable and to minimize the amount of maintenance that needs to be performed. Chromium is a metal that is strong enough to resist wear and tear. It can make an old part look new at a fraction of the price of purchasing a new part. This decision is also better for the environment.

The Initial Inspection

Chrome plating begins by inspecting the piece that will be plated. This is done to determine the process that will need to be performed to achieve the desired end result. After the piece has been inspected, the customer discusses with the chrome plating service about how much it will cost and how much time it will take for the piece to be completed.

Chrome Plating Options

The two chrome options available are nickel chrome plating and hard chrome plating. Hard chrome plating is thicker than nickel chrome plating, and technicians usually apply it to hardened steel. Nickel chrome plating is a more common process.

Stripping

Before the nickel chroming process can begin, the part must be stripped to its bare metal. This includes stripping off all of the dirt, grease, paint, oil, rust, and old plating. If the part is already stripped clean, it will cost less to plate.

Polishing

The polishing process begins next. This involves the removal of surface metal using abrasive tools. Through the use of various tools, the part will be a high-gloss polished part without any pits, scratches, or other impurities. This will leave it more prepared for the chrome plating process.

Cleaning

The part must be cleaned perfectly before it is ready to be plated. The surface is cleaned using a soap, water, and acid solution to avoid a reject. The part is buffed until it has a beautiful shine after being copper plated.

Copper, Nickel, and Chrome Layers

There are several layers of plating before the actual chrome plating, starting with copper plating. The copper offers corrosion protection. The copper can also level the surface and fill in pits.

After cleaning the copper-plated part, a thin layer of nickel is added to provide more luster to the part after the final chrome layer has been added.

The final layer of chrome protects the nickel from tarnishing and provides the part with the chrome appearance. The technicians always apply the chrome using electroplating. Technicians never apply the chrome by melting it, spraying it, or applying it.

Chroming will make your ride look as good as new and will also offer surface protection that will protect your vehicle even under unfavorable conditions. If you believe that your vehicle is a good candidate for chroming, contact

Platinum Surface Coating. We can answer any additional questions you may have about this process.

Share

Tweet

Share

Mail

COVID-19 HOURS

- Mon - Sat

- -

- Sunday

- Closed

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy