Blog Layout

Maintaining Chrome Plating

Chrome plating looks great on vehicle wheels. However, its appearance will deteriorate over time if it is not adequately maintained.

The two things chrome plating needs to maintain its appearance through the years is cleaning and polishing. Without proper cleaning and polishing, chrome plating can lose its mirror finish and begin to appear old and blemished.

The following are seven important things to be aware of when it comes to cleaning and polishing chrome plating:

Importance of Gently Handling Chrome Plating

Whenever you maintain your chrome plating, it's important to remember that chrome is a soft metal.

The fact that chrome is a soft metal contributes to the beauty that it offers as a finish on wheel plating. However, it also means that chrome can easily become damaged if it is not handled gently.

Chrome should never be cleaned roughly or with abrasive substances or fabrics.

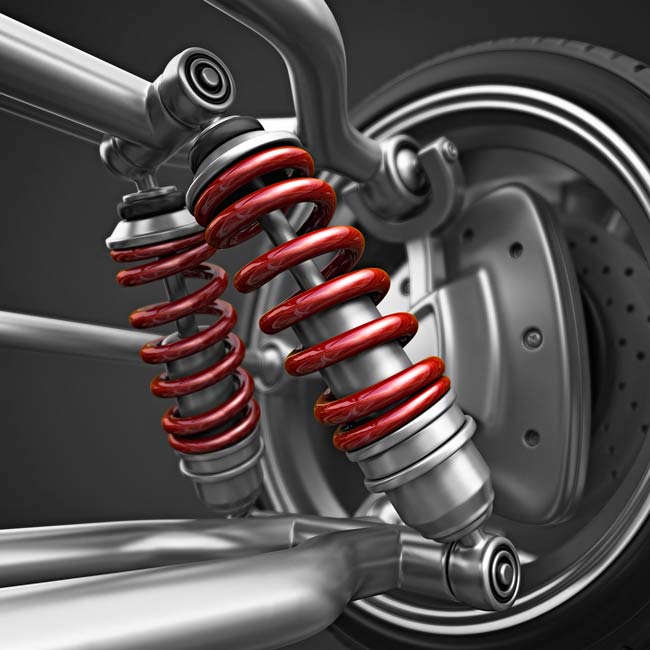

Accumulation of Brake Dust

The most important reason why cleaning and polishing chrome plating is necessary is because brake dust

will appear on plating over time.

Brake dust is given off any time a vehicle runs and the wheels turn and generate friction. Brake dust consists of metal shavings that come off of the rotor when a vehicle is moving.

The more a vehicle is driven, the more brake dust there will be on the chrome plating in the wheels. Keep an eye on plating and take note of brake dust that is developing so you're aware of when it's time for a good cleaning and polish.

Wheel Brush Cleaning

Fortunately, brake dust can easily be cleared away with a gentle wheel brush. Wheel brushes are available that are specifically designed to be gentle enough to handle chrome.

Commercial chrome wheel cleaners are formulated specifically to clean brake dust and other residue from chrome plating. They are non-acidic so that the finish of chrome plating is not damaged.

Chrome wheel cleaners can be used to clear away residue with a gentle wheel brush to prepare the plating for polishing.

Prevention of Water Spots

After a good cleaning, it's important to thoroughly dry off the chrome plating to prevent water spots from forming before the polish is put on.

Plating should be gently towel dried right away to prevent water spots from becoming set on the chrome when the polish is put down.

Use of a Clay Bar for Detailing

After the chrome plating has been cleaned and dried, it's a good idea to rub down the plating with a clay bar

to remove any remaining brake dust.

Clay bar is a gentle tool that will help with detailing. It can sometimes be hard to remove all the brake dust with cleaning alone, so this is where the clay bar comes in.

Placement of a Coat of Polish

Once the chrome plating has been cleaned and all brake dust has been removed, it's time to put a coat of polish down on the plating. You want to use a metal polish that's specifically formulated for chrome.

Rub this polish all over the plating on the wheels. Once a coat of polish has been put down, you can gently rub it into the plating with a spongey ball that is used as an attachment for an electric drill.

Work the ball attachment over the entire surface of the plating until the polish has been dried away.

Tire Dressing

To end the process, you'll want to first take a microfiber towel and get rid of any remaining polish. The last step is to apply some tire dressing over the chrome plating. Avoid using a tire dressing that contains silicone. A water-based dressing will typically offer a better sheen on a polished wheel over the long term.

Share

Tweet

Share

Mail

COVID-19 HOURS

- Mon - Sat

- -

- Sunday

- Closed

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy